-

Differential Pressure Gauge

-

Digital Pressure Gauge

-

Stainless Steel Pressure Gauge

-

Precision Pressure Transmitter

-

Programmable Logic Controller

-

Float Level Switch

-

Pneumatic Valve Positioner

-

Temperature Transmitter Sensor

-

Hart Field Communicator

-

Solenoid Valve

-

Control Valves

-

High Accuracy Flow Meter

-

Submersible Water Pump

-

Pressure Transmitter Manifold

-

Ultrasonic Level Meter

-

Voltage Current Power Meter

Yokogawa In Situ Gas Analyzer TDLS8000 Tunable Diode Laser Spectrometer

| Measurement Object | O2, CO, CO Or CH4, CO2, CO + CO2, H2O, NH3, NH3 + H2O, H2S, HCl Concentration In Combustion Exhaust Gas And Process Gas | Measurement System | Tunable Diode Laser Spectroscopy |

|---|---|---|---|

| Optical Path Length | Standard; 0.5 To 6 M, Max; 30 M (With LAO) | Analog Output | 2 Points, 4 To 20 MA DC |

| Communication | HART, Ethernet | Power Supply | 24 V DC ± 10% |

| Warm-up Time | 5 Min | Protection Degree | IP66, NEMA Type 4X |

| Ambient Operating Temperature | -20 To 55˚C | Storage Temperature | -30 To 70˚C |

| Humidity | 0 To 95%RH At 40˚C | Gas Connections | 1/4 NPT Or Rc1/4 |

| Highlight | Yokogawa In Situ Gas Analyzer,Gas Analyzer TDLS8000 |

||

Yokogawa In-Situ Gas Analyzer TDLS8000 Tunable Diode Laser Spectrometer Yokogawa TDLS8100 TDLS8200 Process Analyzers

Analyzer that realizes real-time feedback and adds value to users through active use such as process control and safety control

- Energy-efficient furnaces, etc., and safety and stable operation contribute to improving OPEX and reducing environmental impact.

- Rapid feedback of process output to the control program, which is essential for optimal operation.

- Release of cumbersome sampling devices and drive components from maintenance.

- Realization of direct measurement under severe process conditions such as high temperature and corrosiveness.

Your benefits

- Measurement with a line using a laser does not miss dangerous thermal unevenness.

- By using a reference cell, low concentration gas is also measured with high accuracy.

- The optical path length can be measured up to 30 m and can be measured up to 1500℃ of hot gas.

- It can also be installed in dangerous places by acquiring Japanese explosion proof authentication, IECEx certification, ATEX certification, FM (US, Canada), KOSHA certification, NEPSI certification, and EAC explosion proof certification.

- The sampling device is unnecessary, and it is easy to install because of its compact design.

- Non-contact type sensor without consumables, i.e. maintenance due to leakage or deterioration is unnecessary.

- It is possible to replace the parts on the spot while they are still installed during repair, and it is possible to reduce the plant shutdown and repair costs due to downtime.

Features: Reasons for high reliability

Enable for safe operation, safety level SIL2, and explosion proof standards.

It conforms to the certification of the safety level SIL2 in accordance with the International standards IEC61508, and can also conform to the SIL3 by duplexing the analyzer.

In addition, the solid body conforms to various explosion proof standards of the area-segmented Zone2/Div2 or Zone1/Div1 and can be installed in dangerous places.

No PC is required for direct simple operation and maintenance with intuitive 7.5-inch color touch screen HMI.

It supports 10 languages: English, German, French, Spanish, Portuguese, Russian, Hungarian, Korean, Chinese, and Japanese.

Provides all information, including trend graphs, and can be remotely installed.

![]()

Standard communication functions that can be checked and adjusted both on-site and at remote locations. (Installation and maintenance cost reduction)

The HART and Modbus TCP communications standards are standardized and can be setup and adjusted by our FieldMate.

Fully field repairable with 50 days of data and spectra storage

Data for 50 days are stored, and can be analyzed when installed in the process.

Compact design for one-man installation without sacrificing ruggedness

Modular design allows replacement and re-operation of components at the site

System configuration according to the plant situation

System configuration according to the plant situation

By connecting to FieldMate via standard HART communication, setting and adjustment can be easily done without HMI. A small display is standard equipment at both ends (sensor control unit and laser unit). The transmittance required to adjust the light axis is always displayed, making it easy to adjust the light axis.

System Configuration with HMI

The 7.5-inch color touch screen HMI YH8000 can improve on-site monitoring and operability.

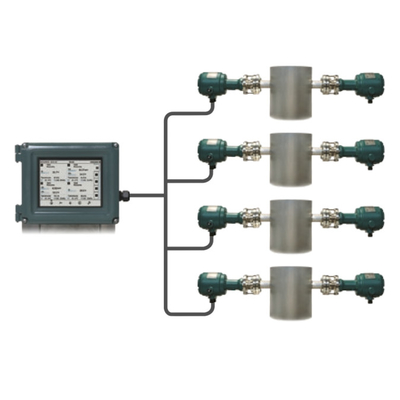

Multi Analyzer Configuration with Remote HMI

Up to 4 TDLS8000 can be connected per HMI for remote control.

Main specifications of TDLS8000

| Measurement object | O2, CO, CO or CH4, CO2, CO + CO2, H2O, NH3, NH3 + H2O, H2S, HCl concentration in combustion exhaust gas and process gas | |||

|---|---|---|---|---|

| Measured components and range | Measured component | Min. range | Max. range | |

| O2 | 0-1% | 0-25% | ||

| CO(ppm) | 0-200 ppm | 0-10,000 ppm | ||

| CO+CH4 | CO | 0-200 ppm | 0-10,000 ppm | |

| CH4 | 0-5 % | |||

| NH3 | 0-30 ppm | 0-50,000 ppm | ||

| H2O (ppm) in non HC | 0-30 ppm | 0-30,000 ppm | ||

| H2O (ppm) in HC | 0-30 ppm | 0-30,000 ppm | ||

| CO (%) | 0-20 % | 0-50 % | ||

| CO (%) + CO2 (%) | 0-30 % | 0-100 % | ||

| NH3 + H2O | NH3 | 0-30 ppm | 0-5,000 ppm | |

| H2O | 0-5 % | 0-50 % | ||

| H2S | 0-5 % | 0-100 % | ||

| CO2 (%) High Range | 0-1 % | 0-5 % | ||

| CO2 (%) Extend.Range | 0-30 % | 0-50 % | ||

| H2O (%) | 0-10 % | 0-100 % | ||

| HCl | 0-50 ppm | 0-5,000 ppm | ||

| Hazardous area classifications | Division 1, Zone 1; Explosion-proof/ Flame-proof type; FM, cFM, ATEX, IECEx (Pending) Division 2, Zone 2; Non-Incendive/Type n; FM, cFM, ATEX, IECEx, KOSHA, NEPSI |

|||

| SIL Certification | The TDLS8000 expect digital output (2 points), digital input (2 points), valve control output (2 points), and digital communications (HART, Modbus/TCP) are certified in compliance with the following standard. IEC 61508:Functional safety of Electrical/electronic/programmable electronic related systems; SIL 2 capability for single analyzer use, SIL 3 capability for dual analyzer use. | |||

| Marine certificate | DNV Type Approval | |||