-

Differential Pressure Gauge

-

Digital Pressure Gauge

-

Stainless Steel Pressure Gauge

-

Precision Pressure Transmitter

-

Programmable Logic Controller

-

Float Level Switch

-

Pneumatic Valve Positioner

-

Temperature Transmitter Sensor

-

Hart Field Communicator

-

Solenoid Valve

-

Control Valves

-

High Accuracy Flow Meter

-

Submersible Water Pump

-

Pressure Transmitter Manifold

-

Ultrasonic Level Meter

-

Voltage Current Power Meter

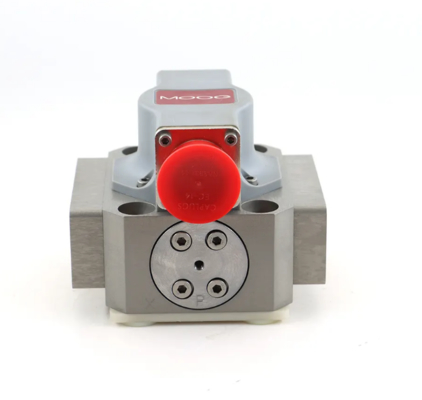

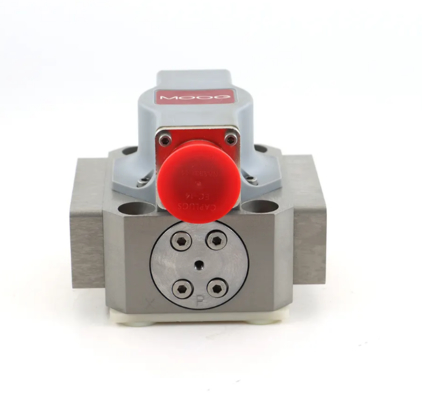

Hydraulic Servo Valve MO-OG Series G761-3033B G761-3034B G761-3002B G761-3003B G761-3004B Hydraulic Solenoid Valve

| Warranty | 1 Year | Valve Type | Proportional Valve |

|---|---|---|---|

| Weight | 5.5 | Maximum Flow Rate | 10L/min |

| Highlight | G761-3033B Hydraulic Servo Valve,MO-OG Hydraulic Servo Valve,G761-3034B Hydraulic Servo Valve |

||

The G761/761 Series flow control servovalves are throttlevalves for 3 and preferably 4-way applications. They area high performance,2-stage design that covers the rangeofrated flows from 4 to 63 l/min (l to 16.5 gpm) at 35 ba(500 psi) valve pressure drop per spool land.

The output stage is a closed center, four.way slidingspool, The pilot stage is a symmetrical double-nozzleand flapper, driven by a double air gap, dry torque motor.Mechanical feedback of spool position is provided by acantilever spring, The valve design is simple and rugged fordependable, long life operation

The design is simple and rugged for dependable, long lifeoperation. The output stage is a closed center, 4 way

sliding spool. The pilot stage is comprised of a symmetrical,double nozzle dry torque motor. The Znd stage spool

position is controlled by a carbide tipped feedback wire.The carbide ball on the end of the feedback wire is a

mandatory design requirement that ensures high accuracy,reliable operation and long service life. All of our servovalves are known for high accuracy and reliable operationeven in the harshest industrial applications.

These valves are suitable for electrohydraulic position,speed,pressure or force control systems with high dynamic

response requirements.

Valve design

Mounting pattern

Maximum operating pressure to ports P, T, A, B

Pilot stage

Rated flow at Ap, 35 bar/spool land

(500 psi/spool land)

Stepresponse time for 0 to 100% stroke

2-stage, with spool and bushing and dry torque motor

15010372-004-04-0-92

315 bar (4,500 psi)

Nozzle Flapper

4 l/min

(1 gpm)

5 ms

10 y/min

(2.5 gpm)

19 l/min

(5 gpm)

38 l/min

(10 gpm)

7 ms

63 l/min

(16.5 gpm)![]()

![]()

![]()

![]()

![]()