-

Differential Pressure Gauge

-

Digital Pressure Gauge

-

Stainless Steel Pressure Gauge

-

Precision Pressure Transmitter

-

Programmable Logic Controller

-

Float Level Switch

-

Pneumatic Valve Positioner

-

Temperature Transmitter Sensor

-

Hart Field Communicator

-

Solenoid Valve

-

Control Valves

-

High Accuracy Flow Meter

-

Submersible Water Pump

-

Pressure Transmitter Manifold

-

Ultrasonic Level Meter

-

Voltage Current Power Meter

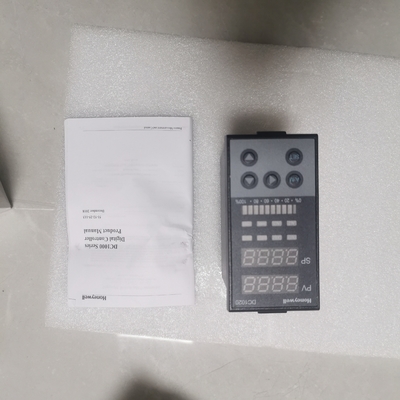

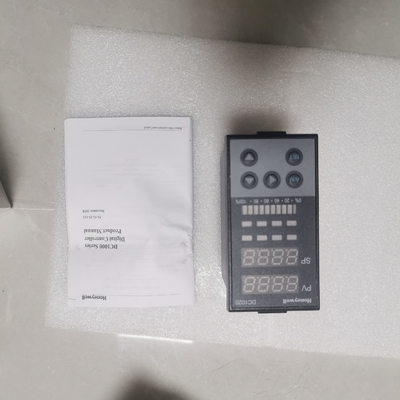

Original Honeywell Temperature Digital Controllers DC1040/1030/1020/1010 in Stock

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Application | Electric Power Transmission | Motor Type | Universal |

|---|---|---|---|

| Material | Plastic | Model Number | DC1020 |

| Highlight | DC1040 Temperature Digital Controller,Original Honeywell Digital Controller |

||

OVERVIEW The DC1000 family of microprocessor based controllers combine a high degree of functionality and reliability at a very low price. Available in 4 different formats : 1/16 DIN, 1/8 DIN, 3/16 DIN, 1/4 DIN. These controllers are ideal for regulating temperature in a variety of applications, including : • Dryers. • Semiconductor packaging / testing. • Plastic processing. • Packaging machinery. • Painting and coating. • Climatic chambers. The DC1000 family provides basic control requirements, plus advanced features such as motor position control, phase angle power control and Setpoint programming. FEATURES DC1030 (3/16 DIN) DC1040 (1/4 DIN) Easy to configure Two different configuration levels provide easy access to parameters. A 4-digit security code prevents unauthorized changes. Parameters can also be hidden to the user to prevent mis-configuration of the unit. Various Control algorithms The DC1000 series of controllers provide several different algorithms: • PID or ON/OFF control. • Heat/Cool algorithms with 2 different PID sets. • Motor position control without slidewire feedback. • Single phase control, with or without zero crossover control. • Three phase control, with or without zero crossover control. Dual display and Bargraph Two large 4 digits displays and one 10 LED bargraph display PV, SP and configuration parameters. Up to 8 LEDs display the status of the different Outputs (Control, Alarm, …) and also provides indication of the Auto/Manual and Programmer states. Setpoint Programming Two programs are available, with a maximum of 8 segments per program. The 2 programs can be linked together to form a single 16 segment program. Extended Alarm capability Three different alarm outputs are available per instrument, 17 alarm modes are configurable. Autotuning capability. Communications RS232 or RS485 Modbus rtu/ASCII protocol is optionally available. Upto 30 DC1000 Controllers can be connected to a single host computer. The host computer can change the SP, monitor the PV, the output or change the configuration of the unit. Remote Setpoint capability. Manual / Automatic modes. Universal Power supply Operates on any voltage from

The term Zero-Crossover means that the SCR's are turned on only when the instantaneous value of the sinusoidal wave is zero. Power is then applied for a several continuous half-cycles and then removed for several half-cycles to achieve the desired load power. CONTROLLER OUT2 Relay OUT1 Relay Motor position is achieved by using time proportional control without the need for slidewire feedback from the motor shaft. Slidewires wear over a period of time, which can result in poor or intermittent control. This type of control reduces maintenance requirements and removes the need for the controller to be calibrated to the motor feed back potentiometer.