-

Differential Pressure Gauge

-

Digital Pressure Gauge

-

Stainless Steel Pressure Gauge

-

Precision Pressure Transmitter

-

Programmable Logic Controller

-

Float Level Switch

-

Pneumatic Valve Positioner

-

Temperature Transmitter Sensor

-

Hart Field Communicator

-

Solenoid Valve

-

Control Valves

-

High Accuracy Flow Meter

-

Submersible Water Pump

-

Pressure Transmitter Manifold

-

Ultrasonic Level Meter

-

Voltage Current Power Meter

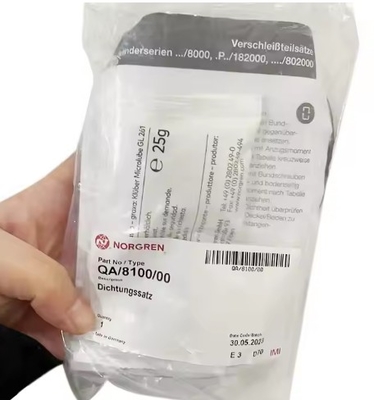

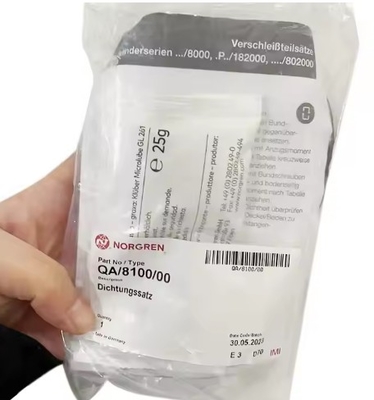

NORGREN Repair Kits Service Kits QA/8100/00 for Automation Industry

| Weight (kg) | 0.4kg | Warranty | 1 Years |

|---|---|---|---|

| Video Outgoing-inspection | Provided | Place Of Origin | Germany |

| Model Number | QA/8100/00 | Condition | 100%New |

| Highlight | NORGREN Repair Kits,Automation Industry Repair Kits,QA/8100/00 Repair Kits |

||

| Cylinder diameter | 100 mm |

|---|---|

| Dimensions - Height | 200 mm |

| Dimensions - Length | 2 mm |

| Dimensions - Width | 200 mm |

| Weight | 0.01 kg |

| Country of Origin | Germany |

| Brand |

IMI Norgren re usable for round barrel cylinders of series …/8000 (with cylinder sizes from 32 to 320 mm), for profile barrel cylinders of series .P../182000 (with cylinder sizes from 32 to 125 mm) and for round and profile barrel cylinders of series …./802000 (with cylinder sizes from 32 to 125 mm). 2. Disassembly of cylinder- Loosen all tie rod nuts or tie rod screws on both sides of the cylinder and remove them as well as – if applicable – tie rods.- Remove front end cover.- Remove piston rod assembly from the barrel.- Separate barrel and rear end cover. 3. Part replacement- Disassemble all seals and – if applicable – the wear ring using suitable tools and taking care not to damage any sealing surfaces.- Thoroughly clean all installation spaces for the seals and lightly grease them afterwards.- Also all new seals have to be lightly greased.- Fit new seals and wear ring taking care not to damage seals and sealing surfaces. If necessary, a proper assembly tool has to be used. 4. Assembly of cylinder- Put a thin layer of grease on the inside surface of the barrel and on the piston rod.- Fill the grease chamber behind the piston rod seal in the front end cover and put a thin layer of grease on the running surface of the piston.- Fit the barrel to the rear end cover and rotate profile barrel into the desired orientation if applicable.- Insert piston rod assembly into barrel taking care not to damage any seals.- Slide front end cover carefully on piston rod in order not to damage the piston rod seal.- If cylinder has tie rods, screw tie rod nuts onto the short threads of the tie rods and insert them into an end cover. Put remaining tie rod nuts – if applicable – into second end cover. Tighten tie rod nuts crosswise to the specified torque.- If cylinder has tie rod screws tighten them crosswise on both end covers to the specified torque.- Check cylinder for leakage (connection front end cover/rear end cover to barrel, piston rod seal) 5. Required grease: Use only the grease from the grease package enclosed in this spare kit. A |