-

Differential Pressure Gauge

-

Digital Pressure Gauge

-

Stainless Steel Pressure Gauge

-

Precision Pressure Transmitter

-

Programmable Logic Controller

-

Float Level Switch

-

Pneumatic Valve Positioner

-

Temperature Transmitter Sensor

-

Hart Field Communicator

-

Solenoid Valve

-

Control Valves

-

High Accuracy Flow Meter

-

Submersible Water Pump

-

Pressure Transmitter Manifold

-

Ultrasonic Level Meter

-

Voltage Current Power Meter

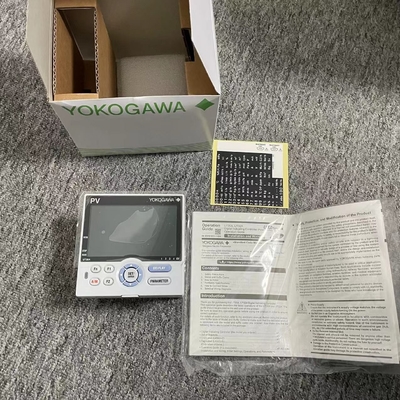

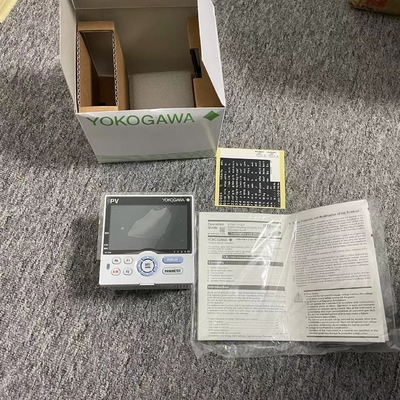

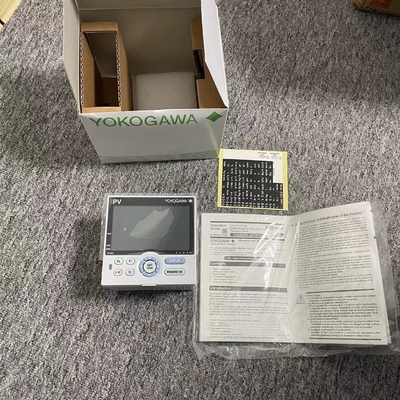

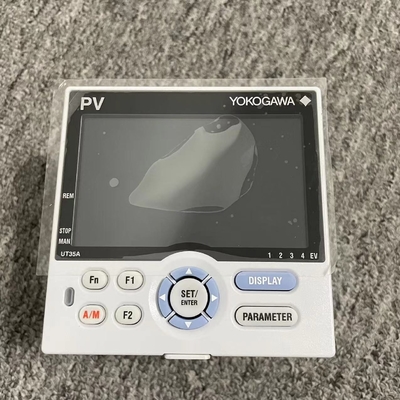

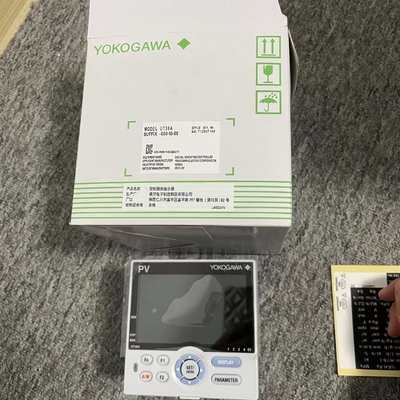

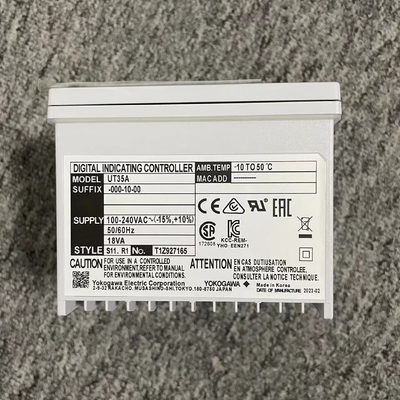

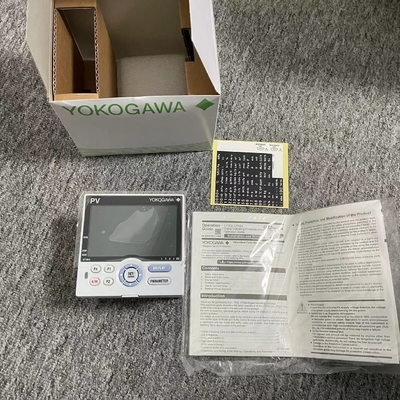

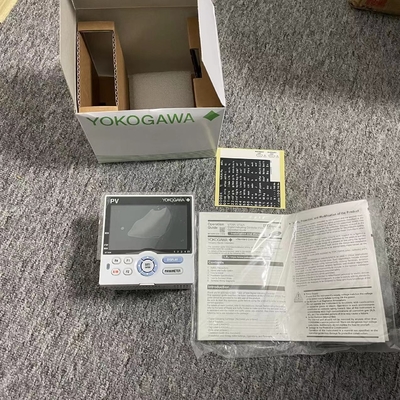

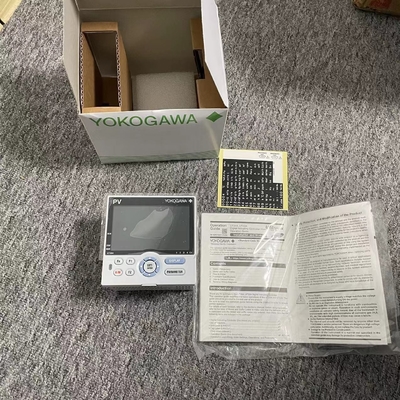

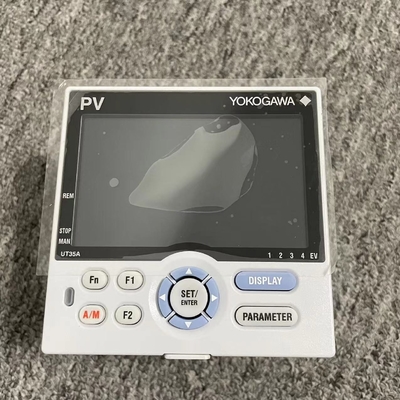

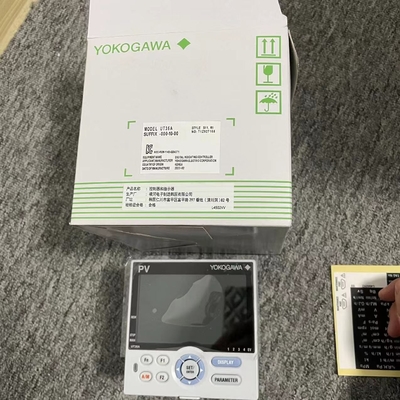

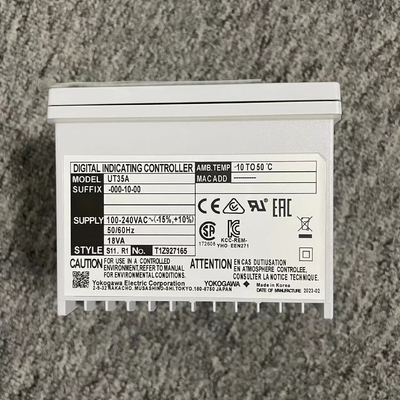

UT35A-001-10-00 Original Temperature Digital Controller for Industrial Applications

| Place Of Origin | Original | Type | UT35A-001-11-00 |

|---|---|---|---|

| Model Number | UT35A-001-11-00 | Condition | New&original |

| Warranty | 1 Year | Shipping Method | Fedex/DHL/UPS/TNT/EMS/Others |

| Highlight | Industrial Applications Digital Controller,UT35A-001-10-00 Digital Controller,Original Temperature Digital Controller |

||

The UT35A and UT32A temperature controllers employ an easy-to-read, 14-segment large color LCD display, along with navigation keys, thus greatly increasing the monitoring and operating capabilities. A ladder sequence function is included as standard. The short depth of the controller helps save instrument panel space. The UT35A/UT32A also support open networks such as Ethernet communication.

UT35A and UT32A Temperature Controller Features

- 4 target setpoints (PID numbers) available as standard

- 3 alarm independent common terminals available as standard

- Ladder sequence programs can be built

- Simple operation

- Up to 8 DOs (combinations available)

- Multiple language operation manual (Japanese, English, German, French, Spanish, Chinese and Korean) available. Please specify the desired language when ordering.

- Detailed code model available to customize specifications best suited to you.

-

Advanced Control

Control Modes

The control mode allows easily configuring settings and making changes with parameters.

- Single-loop control

-

5 Built-in Control Types

- PID control

- ON/OFF control (1 point of hysteresis)

- ON/OFF control (2 points of hysteresis)

- Two-position, two-level control

- Heating/cooling control

For the correspondence between the above control mode and control types for each model, please refer to the specifications.

Ladder Sequence Control

With built-in ladder sequence control, the range of applications are dramatically increased. This feature is standard in all the UTAdvanced controllers (except UM33A). The ladder sequence control function can replace a small PLC required by the application. Sequence control and PID control can be performed simultaneously.

- Monitoring and control of external machinery

E.g.: Lamps, switches, timers - Solve digital input/output logic functionality easily.

Number of basic command types: 13

Number of application command types: 73 -

[Example of ladder instruction] [Example of ladder programming]

Application Examples of Ladder Sequence Program

Alarm Sequence Control Circuits Can be Reduced

The ladder sequence program is built in the UTAdvanced as standard. The ladder sequence function enables monitoring and controlling peripheral devices such as relays, thus making it possible to reduce costs.[Conventional]

Alarm action was built by a sequence control circuit (relay, timer, etc.) outside of the controller.

[UTAdvanced]

Alarm action is built by the ladder sequence program inside the UTAdvanced, thus making it possible to reduce costs.

Host System Load is Reduced

[Conventional]

Various types of analog data were captured into the host system (PLC, etc.) and calculated, and the results were processed by the field controller for control via a command.[UTAdvanced]

The UTAdvanced with up to 4 analog inputs* enables various types of analog data to be captured directly into the controller and calculated by the ladder program, thus reducing the system-building load of the host. Action: Various types of analog data were captured into the host system (PLC, etc.) and calculated, and the results were processed by the field controller for control via a command.

* In the case of the UT55A

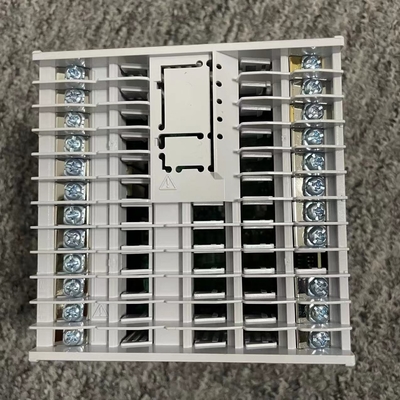

Universal Input/Output

Select Input and Output Types via ConfigurationUniversal Input

Select from TC, RTD, mV/DC voltage and DC current. (DC current input: No shunt resistor required)

The input type and range is user selectable via the front panel or by using the LL50A parameter setting software.  ±0.1% Indication Accuracy.

±0.1% Indication Accuracy.- Connect up to two 2-wire transmitters simultaneously.

-

All instruments have a 15 V Loop Power Supply (15 V LPS) for a transmitter.

In addition, a 24 V LPS is also available simultaneously for some instruments as optional function.

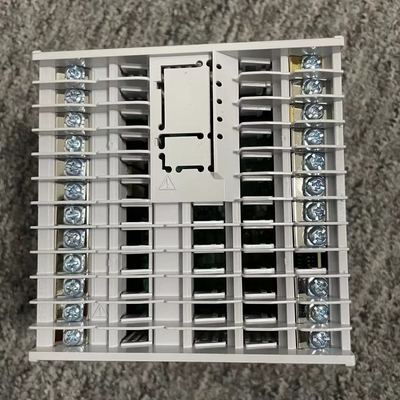

Universal Output

User selectable for relay, Voltage pulse and current outputs.

- Relay output: ON/OFF control, time-proportional PID control

- Voltage pulse output: time-proportional PID control

- Current output: continuous PID control

-

Heating/cooling control has two sets of universal outputs.

- Any combinations of relay, pulse and current outputs are available.

-

Drive a motorized control valve by using position-proportional PID.

- The position-proportional PID control function has two sets of relay outputs for direct/reverse rotation of motorized control valve.

- The slide wire input to feed back the valve position is also available.

-

Auto-tuning (AT) Function

The following conditions can be set in order to increase the accuracy of calculating PID constants using AT .

- Two types of algorithms to calculate PID constants are available for selection.

Advanced Control

Control Modes

The control mode allows easily configuring settings and making changes with parameters.

- Single-loop control

-

5 Built-in Control Types

- PID control

- ON/OFF control (1 point of hysteresis)

- ON/OFF control (2 points of hysteresis)

- Two-position, two-level control

- Heating/cooling control

For the correspondence between the above control mode and control types for each model, please refer to the specifications.

Ladder Sequence Control

With built-in ladder sequence control, the range of applications are dramatically increased. This feature is standard in all the UTAdvanced controllers (except UM33A). The ladder sequence control function can replace a small PLC required by the application. Sequence control and PID control can be performed simultaneously.

- Monitoring and control of external machinery

E.g.: Lamps, switches, timers - Solve digital input/output logic functionality easily.

Number of basic command types: 13

Number of application command types: 73 -

[Example of ladder instruction] [Example of ladder programming]

Application Examples of Ladder Sequence Program

Alarm Sequence Control Circuits Can be Reduced

The ladder sequence program is built in the UTAdvanced as standard. The ladder sequence function enables monitoring and controlling peripheral devices such as relays, thus making it possible to reduce costs.[Conventional]

Alarm action was built by a sequence control circuit (relay, timer, etc.) outside of the controller.

[UTAdvanced]

Alarm action is built by the ladder sequence program inside the UTAdvanced, thus making it possible to reduce costs.

Host System Load is Reduced

[Conventional]

Various types of analog data were captured into the host system (PLC, etc.) and calculated, and the results were processed by the field controller for control via a command.[UTAdvanced]

The UTAdvanced with up to 4 analog inputs* enables various types of analog data to be captured directly into the controller and calculated by the ladder program, thus reducing the system-building load of the host. Action: Various types of analog data were captured into the host system (PLC, etc.) and calculated, and the results were processed by the field controller for control via a command.

* In the case of the UT55A

Universal Input/Output

Select Input and Output Types via ConfigurationUniversal Input

Select from TC, RTD, mV/DC voltage and DC current. (DC current input: No shunt resistor required)

The input type and range is user selectable via the front panel or by using the LL50A parameter setting software.  ±0.1% Indication Accuracy.

±0.1% Indication Accuracy.- Connect up to two 2-wire transmitters simultaneously.

-

All instruments have a 15 V Loop Power Supply (15 V LPS) for a transmitter.

In addition, a 24 V LPS is also available simultaneously for some instruments as optional function.

Universal Output

User selectable for relay, Voltage pulse and current outputs.

- Relay output: ON/OFF control, time-proportional PID control

- Voltage pulse output: time-proportional PID control

- Current output: continuous PID control

-

Heating/cooling control has two sets of universal outputs.

- Any combinations of relay, pulse and current outputs are available.

-

Drive a motorized control valve by using position-proportional PID.

- The position-proportional PID control function has two sets of relay outputs for direct/reverse rotation of motorized control valve.

- The slide wire input to feed back the valve position is also available.

-

Auto-tuning (AT) Function

The following conditions can be set in order to increase the accuracy of calculating PID constants using AT .

- Two types of algorithms to calculate PID constants are available for selection.