-

Differential Pressure Gauge

-

Digital Pressure Gauge

-

Stainless Steel Pressure Gauge

-

Precision Pressure Transmitter

-

Programmable Logic Controller

-

Float Level Switch

-

Pneumatic Valve Positioner

-

Temperature Transmitter Sensor

-

Hart Field Communicator

-

Solenoid Valve

-

Control Valves

-

High Accuracy Flow Meter

-

Submersible Water Pump

-

Pressure Transmitter Manifold

-

Ultrasonic Level Meter

-

Voltage Current Power Meter

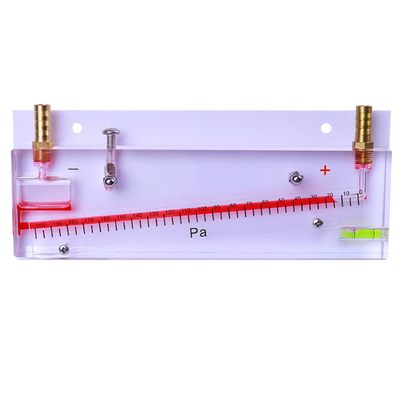

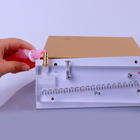

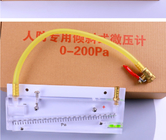

Slash Negative Gas Inclined Tube Manometer Fire Engineering 0-200pa

| Size | 196mm*84mm | Model | DP-200 |

|---|---|---|---|

| Working Temperature | -10-60 | Pressure Range | 0-200pa |

| Accuracy | 0.5 | Product Name | Inclined Tube Manometer |

| Highlight | Gas Inclined Tube Manometer,Inclined Tube Manometer Fire Engineering,Gas slant tube manometer |

||

MC DP-200 Slash negative 0-200pa pressure gauge use in fire engineering Made in China

Sepcification

|

0.5 |

|

DP-200 |

|

gas |

|

pressure gauge |

|

-10-60 |

|

0-200pa |

|

|

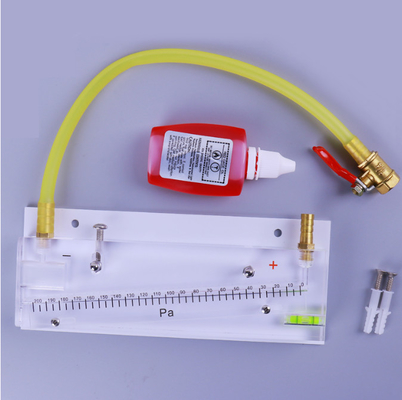

Installation instructions:

Connect the instrument with a less than 5 screws on the wall or installed on the vertical objects, adjust the instrument status (with the level of the instrument), then tighten the screws. Unscrew the reservoir, reservoir in joint spare cylinder in the liquid until the zero position calibration tables, unscrew the connectors.Note:Positive pressure measurement: when connecting pipe joint in instrument port (+)When measuring the negative pressure: port connection pipe joint in the instrument (-)When measuring the differential: will take over high pressure in the instrument port (+) low voltage interface meet in instrument port (-)Special reminder: 12 months to replace liquid at a time.

![]()

![]()

The performance characteristics

1. instrument is divided into chrome mixed mass type structure and all stainless steel structure; All stainless steel structure corrosion resistance is strong;

2. control table for symmetrical design, high static pressure resistance, resistance to overload ability;

3. using special high-performance play single sex element, transmission error is small, indicating high accuracy;

4. high reliability and stability for the work;

5. control pressure within the range from zero to full star cheng continuous adjustable;

6. can take on a lower limit alarm switch output.

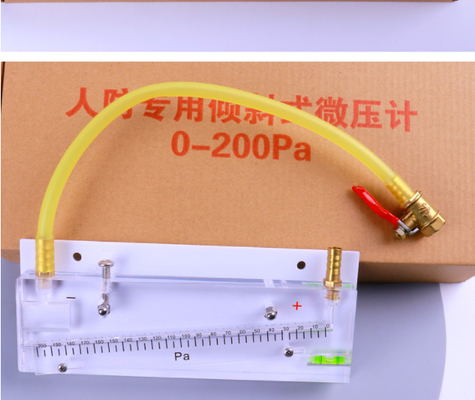

Usage

Air tightness measurement work to detect project for internal use.To sealing, to ensure the poison of civil air defense engineering external and internal agents will not enter the project, to ensure the safety of staff. Check inside and outside differential pressure piezometric tube.Internal civil air defence works to maintain a positive pressure in wartime.Wartime internal pressure should be greater than the external, civil air defence works to prevent external polluted air inflow, airtight measuring tube is used to measure the matching engineering of inside and outside differential pressure.

![]()

![]()

Many thread ball valve are optional

![]()

Safe operation

1. Differential pressure meter operators should be familiar with the working principle, performance characteristics, detection points and detection items of various instruments

2. Differential pressure meter operators print production reports and monitoring reports regularly every day to reflect the factory's production and operation situation in time

3. Regularly inspect the differential pressure meter at each test point on site and make a record. If abnormal situation is found, it shall be handled and reported in time.

4, rainy weather to the scene inspection differential pressure timing, operators should pay attention to prevent electric shock

5, all kinds of detection differential pressure meter primary sensor should be cleaned and descaled as required.

6. The printing mechanical parts of the microcomputer system should be lubricated regularly.

7. If the differential pressure meter fails, the transmitter and converter shall not be disassembled or unloaded at will.

8, repair differential pressure gauge, should do protective measures. All kinds of meters that are not used for a long time or soaked in water due to improper use should be dried before use.

9. Computer software that is not used for operation in the factory is strictly forbidden to run on the computer on the network. When running, do not exit the computer software or insert the floppy disk.

10, regular maintenance of various components of the differential pressure meter, probe, converter, calculator, conduction TV and secondary instruments, etc. Keep all parts complete, clean, no rust, dial scale scale clear, nameplate, mark, seal intact; Clean central control room; The microcomputer system works well: the instrument well is clean and there is no water

![]()

The preparatory work

1, plus the working liquid to work surface tilt measuring scale of pipe near zero, and then cover tightly with liquid cover.Drive

2, sparkling light blow with the mouth, and liquid level rise to observe any air bubbles.

3, leveling zero rotating screw, level instrument.

4, leak detection card dead rubber tube, observe whether the liquid level drops, if he does not fall, not leak.

![]()