-

Differential Pressure Gauge

-

Digital Pressure Gauge

-

Stainless Steel Pressure Gauge

-

Precision Pressure Transmitter

-

Programmable Logic Controller

-

Float Level Switch

-

Pneumatic Valve Positioner

-

Temperature Transmitter Sensor

-

Hart Field Communicator

-

Solenoid Valve

-

Control Valves

-

High Accuracy Flow Meter

-

Submersible Water Pump

-

Pressure Transmitter Manifold

-

Ultrasonic Level Meter

-

Voltage Current Power Meter

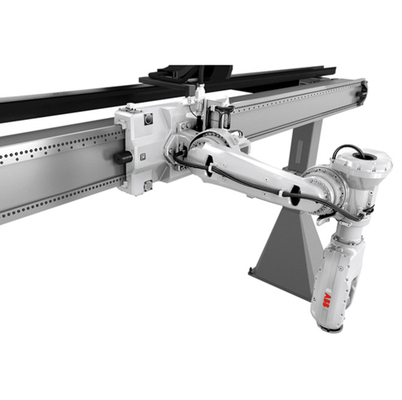

Irb4600 6 Axis Robotic Arm Milling 45kg Payload Reach 2050mm

| Axis | 6 | Reach | 2050mm |

|---|---|---|---|

| Weight | 425kg | Payload | 60kg |

| Highlight | 6 Axis Robotic Arm Milling,Robotic Arm Milling Irb4600,6 Axis Robot Milling 2050mm |

||

| Mounting | Floor, shelf, inverted or tilted | |

|---|---|---|

| Controller | IRC5 Single cabinet | |

| Armload | 20kg | |

| Height | 1727mm | |

| Position repeatability | 0.06mm | |

| Path repeatability | 0.46mm |

6 Axis Milling Robot Irb4600 45kg Payload Reach 2050mm Highly Productive Robotic Arm Milling

Features

The IRB 4600 is a highly efficient general-purpose robot, optimized for shorter beat times, with a slim body that works well in high-density work units. The IRB 4600 makes the layout of production units more compact, achieving both capacity and quality improvements and pushing production efficiency to a new level.

Shortest cycle times

the IRB 4600 is compact and lightweight, achieving ABB's highest acceleration. Combined with its ultra-fast operating speed, the IRB 4600 achieves a minimum cycle time reduction of 25% compared to industry standards. In operation, the robot can always maintain the highest acceleration while avoiding obstacles and tracking paths, thus improving productivity and efficiency.

Ultra-wide working range

You can position the IRB 4600 in the most favourable way with regard to reach, cycle time and auxiliary equipment. Flexible mounting with floor, tilted, semishelf or inverted mounting is very useful when you are simulating the best position for your application.

Compactness

The small footprint, the slim swing base radius around axis 1, the fine elbow behind axis 3, the small lower and upper arms, and the compact wrist all contribute to the most compact robot in its class. With the IRB 4600 you can create your production cell with reduced floorspace by placing the robot closer to the served machines, which also increases your output and your productivity.

Best protection available

ABB has the most comprehensive protection program on the market and it will be even further enhanced with the IRB 4600. Foundry Plus includes IP 67, resistant paint, rustprotected mounting flange and protection for molten metal spits on non-moving cables on the rear of the robot and extra protection plates over the floor cable connections on the foot.

Optimize and go sharp

To get the IRB 4600 ready for the targeted applications you have access to high performing workpiece positioners, track motions, and the motor and gear unit range.

Main applications

| Brand | ABB |

| Model | IRB4600 |

| Protection | Standard IP67, as option Foundry Plus 2 |

| Mounting | Floor, shelf, inverted or tilted |

| Reach | 2050mm |

| Weight | 425 kg |

![]()

| Working range | |

| Axis 1 arm rotation | +180° to -180° |

| Axis 2 arm | +150° to -90° |

| Axis 3 arm | +75° to -180° |

| Axis 4 wrist | +400° to -400° |

| Axis 5 bend | +120° to -125° |

| Axis 6 turn | +400° to -400° |