-

Differential Pressure Gauge

-

Digital Pressure Gauge

-

Stainless Steel Pressure Gauge

-

Precision Pressure Transmitter

-

Programmable Logic Controller

-

Float Level Switch

-

Pneumatic Valve Positioner

-

Temperature Transmitter Sensor

-

Hart Field Communicator

-

Solenoid Valve

-

Control Valves

-

High Accuracy Flow Meter

-

Submersible Water Pump

-

Pressure Transmitter Manifold

-

Ultrasonic Level Meter

-

Voltage Current Power Meter

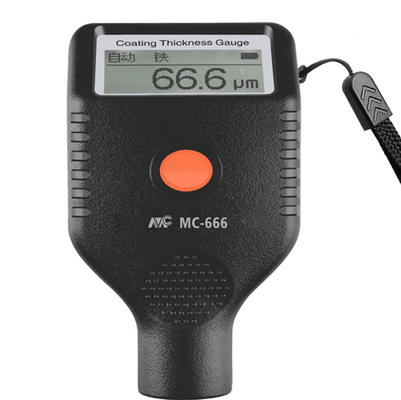

2.5% Accuracy Digital Pressure Gauge MC-666 Car Paint Thickness Gauge

| The Accuracy | 2.5% | Power | Battery |

|---|---|---|---|

| Weight | 80g | Model | MC-666 |

| Dimensions | 114*53*25mm | Color | Black |

| Highlight | 2.5% Accuracy Digital Pressure Gauge,MC-666 Car Paint Thickness Gauge,2.5% Accuracy paint depth gauge |

||

MC MC-666 2.5% accuracy with Battery Gauge Meter Car Paint Depth Gauge Coating Thickness Paint Thickness

Thickness Gauge

A thickness gauge is a gauge used to measure the thickness of materials and objects. In industrial production, it is often used to continuously or sample the thickness of products (such as steel plates, steel strips, films, paper, metal foils and other materials).

There are radioactive thickness gauges that use the penetration characteristics of alpha rays, beta rays, and gamma rays; there are ultrasonic thickness gauges that use ultrasonic frequency changes; there are eddy current thickness gauges that use the principle of eddy current; and they use the principle of mechanical contact measurement. Thickness gauge, etc.

Specification

| The accuracy | 2.5% |

| power | Battery |

| dimensions | 114*53*25mm |

| weight | 80g |

| model | MC-666 |

| Brand | MC |

| Warranty | 1 year |

| Color | black |

Introduce

The thickness gauge can be used to measure the thickness of the rolled plate and strip on-line and output it in the form of electrical signals. The electrical signal is output to the display and the automatic thickness control system to realize the automatic thickness control (AGC) of the strip thickness. At present, there are four common thickness gauges: γ-ray, β-ray, X-ray and isotope ray, etc., all of which are placed at the exit or entrance side of the strip mill. When designing and installing the thickness gauge, it should be as close as possible to the work roll when possible, in order to reduce the lag adjustment time of the plate thickness.

![]()

![]()

![]()

![]()

![]()

Main type

An instrument used to determine the thickness of the material itself or the thickness of the material surface covering layer. The thickness of some components must be measured during manufacturing and maintenance to understand the thickness of the material, the uniformity of each point, and the degree of material corrosion and wear; sometimes the thickness of the covering layer on the surface of the material must be measured to ensure product quality and production safety. According to different measurement principles, there are four commonly used thickness gauges: ultrasonic, magnetic, eddy current, and isotope.

The speed of sound of ultrasonic in various media is different, but the speed of sound in the same medium is a constant. When the ultrasonic wave propagates in the medium, it will be reflected when it encounters the second medium. The interval time from the transmission to the reception of the ultrasonic pulse is measured, and this interval time can be converted into the thickness. This type of thickness gauge is the most widely used in the power industry. It is often used to determine the thickness of boiler drums, heating surface pipes, pipes, etc., and also to check the structural dimensions of workpieces. This type of thickness gauge is mostly portable, similar in size to a small semiconductor radio, and the thickness value display is mostly digital. For steel, the maximum measured thickness is about 2000 mm, with an accuracy of ±0.01~±0.1 mm.

When the magnetic thickness gauge measures the magnetoresistance of various magnetic materials, the measured value will vary due to the thickness of the non-magnetic coating on the surface. This change can be used to measure the thickness of the covering layer. It is often used to measure the thickness of the sprayed aluminum layer, plastic layer, electroplating layer, phosphating layer, paint layer, etc. on the surface of ferromagnetic metal.

Eddy current thickness gauge When the probe coil carrying high-frequency current is placed on the surface of the metal to be measured, eddy current is generated in the metal body due to the action of the high-frequency magnetic field, and the magnetic field generated by this eddy current reacts on the probe coil, causing its impedance to change The amount of this change is related to the distance between the probe coil and the metal surface (that is, the thickness of the covering layer), so the thickness of the metal surface covering layer can be indirectly measured according to the change in the impedance of the probe coil. It is often used to measure the thickness of the oxide film on aluminum or other insulating coatings on the surface of aluminum and copper.

The isotope thickness gauge uses the different principles of different material thickness to absorb and scatter radiation, and can measure the thickness of metal materials such as thin steel plates, thin copper plates, thin aluminum plates, silicon steel sheets, alloy sheets, rubber sheets, plastic films, paper, etc. Commonly used isotope rays include gamma rays and beta rays.

Note for measurement:

⒈When testing, pay attention to the collective metal magnetic properties and surface roughness of the standard plate should be similar to the test piece.

⒉The side head is vertical to the surface of the sample during measurement.

⒊Pay attention to the critical thickness of the base metal when measuring. If it is greater than this thickness, the measurement will not be affected by the thickness of the base metal.

⒋When measuring, pay attention to the influence of the curvature of the test piece on the measurement. Therefore, it is unreliable when measuring on a curved specimen surface.

⒌Before measuring, pay attention to whether other electrical equipment around will generate magnetic field, if it will interfere with the magnetic thickness measurement method.

⒍Be careful not to measure at the inner corner and near the edge of the test piece when measuring, because the general thickness gauge is very sensitive to sudden changes in the surface shape of the test piece.

⒎Keep the pressure constant during measurement, otherwise it will affect the measured reading.

⒏When testing, pay attention to the direct contact between the probe of the instrument and the test piece, so the ultrasonic thickness gauge is performing the opposite head to remove the attached material

Application

1. The laser thickness gauge uses the principle of laser reflection to measure the thickness of the product by measuring and observing the microscopic geometry of the processed surface of the parts in the mechanical manufacturing. It is a non-contact dynamic measuring instrument. It can directly output digital signals and connect with industrial computers, and quickly process data and output deviation values to various industrial equipment.

2. When the X-ray thickness gauge uses X-rays to penetrate the material to be measured, the change in the intensity of X-rays is related to the thickness of the material. Cangzhou Oupu is a non-contact dynamic measuring instrument to measure the thickness of the material. . It takes PLC and industrial computer as the core, collects calculation data and outputs the target deviation value to the rolling mill thickness control system to achieve the required rolling thickness. Main application industries: non-ferrous metal strip and foil processing, metallurgical industry strip processing.

3. Paper thickness gauge: suitable for measuring the thickness of various films, paper, cardboard and other sheet materials below 4mm.

4. Thin film thickness gauge: used to measure the thickness of thin films, sheets and other materials. It has a wide measurement range and high measurement accuracy. It has the characteristics of data output, zero setting at any position, metric and inch conversion, automatic power-off and so on.

5. Coating thickness gauge: used to measure the thickness of the coating on ferrous and non-ferrous metal substrates.

6. Ultrasonic thickness gauge: Ultrasonic thickness gauge is based on the principle of ultrasonic pulse reflection for thickness measurement. When the ultrasonic pulse emitted by the probe reaches the interface of the material through the measured object, the pulse is reflected back to the probe, and the ultrasonic pulse is accurately measured. The time of propagation in the material determines the thickness of the material being measured. All kinds of materials that can make ultrasonic waves propagate in its interior at a constant speed can be measured by this principle.

![]()

Electrostatic interference resistance, moisture, to adapt to the complex working environment

![]()

South, north, are useful to adapt - 20 ~ 50 ℃ high temperature environment

![]()

Automatic identification of magnetic and non-magnetic substrate

Buying a used car is the best way1Car accidentLike accident car after maintenance, it is difficult to detect from the appearance, often can muddle through, fooling some novice

Generally the original automotive paint thickness between 100-200 - um, and patched up the thickness of the paint can significantly increase, but a little um, 500-1000 standard name: the QCT paint quality standard, 484-1999. Under which the first: for cheap introductory pure affordable subcompacts (naked price is lower than 50000) standards, its paint thinner is not less than 90 um, we paint thickness requirements for this class models can be said to be low. Less than 90 um as paint to cut corners.Second: the standard is 50000 yuan for the word of any type of standard, this standard will be improved; Low cannot be lower than 120 um hard Numbers). Less than 120 um as jerry.

![]()

![]()

Method of measurement:

1 body side door five points a. B, C.D.E

2 measured three times average per point

3 together, the average of the five averaged

4 again to get the average thickness of each part of the body