-

Differential Pressure Gauge

-

Digital Pressure Gauge

-

Stainless Steel Pressure Gauge

-

Precision Pressure Transmitter

-

Programmable Logic Controller

-

Float Level Switch

-

Pneumatic Valve Positioner

-

Temperature Transmitter Sensor

-

Hart Field Communicator

-

Solenoid Valve

-

Control Valves

-

High Accuracy Flow Meter

-

Submersible Water Pump

-

Pressure Transmitter Manifold

-

Ultrasonic Level Meter

-

Voltage Current Power Meter

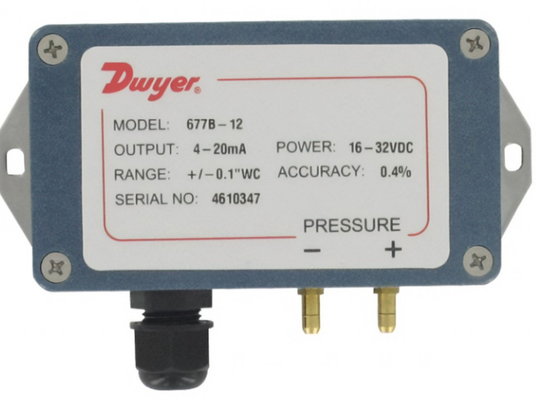

100 Bar Precision Pressure Transmitter 302 SS 100KPa 0.4% FS

| Product Name | Differential Pressure Transmitter | Accuracy | ±0.4% FS |

|---|---|---|---|

| Stability | ±1% FS/yr | Pressure Limit | 15 Psi (100 KPa) |

| Power Requirements | 16 To 32 VDC | ||

| Highlight | 100 Bar Precision Pressure Transmitter,Precision Pressure Transmitter 302 SS,100KPa Stainless Steel Pressure Transmitter |

||

| Wetted Materials: | 302 SS, glass, nickel, silicone rubber and brass. | |

|---|---|---|

| Accuracy: | ±0.4% FS* at room temperature. *RSS includes non-linearity, hysteresis and non-repeatability. | |

| Stability: | ±1% FS/yr. | |

| Temperature Limits: | > Operating and Compensated: 0 to 185°F (-18 to 85°C); | |

| Pressure Limit: | 15 psi (100 kPa). | |

| Thermal Effects: | (Includes zero and span) <0.028% FS/°F, 0 to 185°F (-18 to 85°C). | |

| Power Requirements: | 16 to 32 VDC. | |

| Output: | 4 to 20 mA DC, 2-wire. | |

| Zero and Span Adjustments: | Internally accessible potentiometers, noninteractive. | |

| Response Time: | Approximately 10 ms. | |

| Max. Loop Resistance: | DC: 0 to 800 Ohms. | |

| Process Connection: | 3/16" OD barbed brass pressure fitting. | |

| Enclosure Rating: | NEMA 4 (IP65). | |

| Weight: | 11.5 oz (330 g). | |

| Agency Approval: | CE. |

Dwyer differential 302 SS 15 psi (100 kPa) ±0.4% FS pressure transmitter 677b-12 pressure transmitter 100bar

Series 677B Differential Pressure Transmitters are designed to measure pressures as low as 0.1 in w.c. with ±0.4% accuracy. Use Series 677B for building energy management systems, environmental pollution control, oven pressurization, lab and fume hood control, HVAC and VAV applications. The transmitter features 15 psid overpressure, reverse polarity protection and EMI/RFI protection. Internal regulation permits use with unregulated DC power supplies. The NEMA 4 housing allows for versatile mounting locations and integral mounting tabs simplify installation

Specification

| Wetted Materials: | 302 SS |

| Accuracy: | ±0.4% FS |

| Stability: | ±1% FS/yr |

| Pressure Limit: | 15 psi (100 kPa) |

![]()

![]()

Mounting Series 677B is designed for mounting by using the two (2) slots (suitable for #6 and #8 screws) that are provided on the mounting baseplate. For optimum performance, isolate the instrument from vibration and provide relatively clean, dry air to the pressure ports. Note: Even though there is no flow through the 677B, a filter is located in both the high and low pressure ports for use in extreme dust or moisture conditions. In most applications, preferred installation is with the baseplate mounted vertically and located on a flat surface in a junction box or attached to a nearby beam. Quick and easy field replacement is possible by removing the two case screws that hold the housing to the baseplate and lifting the housing free. The baseplate will remain mounted and can be used with the replacement units housing

![]()

![]()

Electrical The Series 677B is a two (2) wire circuit (+SUPPLY, -RECEIVER) with a 4 to 20 mA output. The unit is calibrated at the factory using a 250 ohm load at 24 VDC.

WIRING DIAGRAM FOR 677B SERIES

![]()

Calibration

The 677B series is factory calibrated and should require no field adjustment. However, the zero adjustment is provided near the screw terminal strip. Whenever possible, any zero and/or span offsets should be corrected by software adjustment in the user’s control system. Use the zero and span adjustments on the 677B series only if absolutely necessary. The 677B series is calibrated in the vertical position at the factory (baseplate vertical). For use in any other orientation, position the unit and follow the adjustment procedure listed below. If a change in range is needed, contact the Customer Service Department for a replacement in the appropriate range.

Zero Adjustment

While monitoring the current output with both pressure ports open to atmosphere, the zero may be adjusted. For unidirectional pressure changes, turn the zero adjustment screw until a reading of 4 mA (± .16 mA) is achieved. For bidirectional ranges, set the zero to 12 mA (± .16 mA).

MAINTENANCE

Upon final installation of the Series 677B Transmitter, no routine maintenance is required. The Series 677B is not field serviceable and should be returned if repair is needed (field repair should not be attempted and may void warranty). Be sure to include a brief description of the problem plus any relevant application notes. Contact customer service to receive a return goods authorization number before shipping.