-

Differential Pressure Gauge

-

Digital Pressure Gauge

-

Stainless Steel Pressure Gauge

-

Precision Pressure Transmitter

-

Programmable Logic Controller

-

Float Level Switch

-

Pneumatic Valve Positioner

-

Temperature Transmitter Sensor

-

Hart Field Communicator

-

Solenoid Valve

-

Control Valves

-

High Accuracy Flow Meter

-

Submersible Water Pump

-

Pressure Transmitter Manifold

-

Ultrasonic Level Meter

-

Voltage Current Power Meter

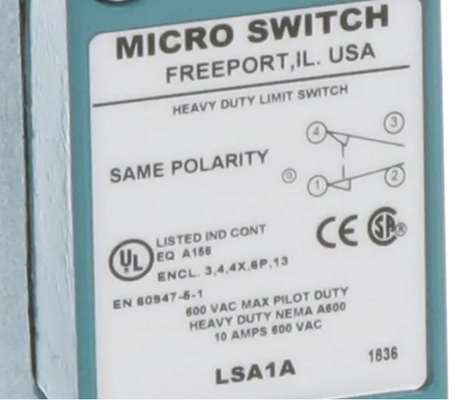

600VAC 10A Heavy Duty Limit Switch Side Rotary Silver Plated

| Current Rating | 10 A | Head Type | Side Rotary Head |

|---|---|---|---|

| IP Rating | IP65 ; IP66 ; IP67 | Material | Zinc Die-Cast (Housing) |

| Operating Temperature | -20 To 121 °C | Warranty | 1 Year |

| Highlight | 10A Heavy Duty Limit Switch,Heavy Duty Limit Switch Side Rotary,Silver Plated heavy duty micro switch |

||

High quality Honeywell HDLS Series Heavy Duty Limit Switch LSA1A 600VAC, 10A

Introduction

Honeywell’s MICRO SWITCH heavy-duty limit switches’ modular construction allows for a wide variety of actuator styles, operating heads, and electrical circuitry options. The plug-in versions greatly reduce downtime on production lines with high actuation rates as replacement of the switch is accomplished in seconds. The base receptacle contains all the wiring and conduit connection while the switching component with operating head easily assembles to the base and is attached with two screws.

Specification

| Rated operational current (Ie) | 1.2 A, 0.1 A |

| Rated thermal current | 10 A, 2.5 A |

| Rated insulation voltage | 600 V |

| Pollution degree | 3 |

| Certifications | UL, CE, CSA, CCC |

| Housing type | HDLS Plug-in, HDLS Non-Plug-in |

Features

Performance characteristic

![]()

Honeywell’s MICRO SWITCH heavy-duty limit switches’ modular construction allows for a wide variety of actuator styles, operating heads, and electrical circuitry options. The plug-in versions greatly reduce downtime on production lines with high actuation rates as replacement of the switch is accomplished in seconds. The base receptacle contains all the wiring and conduit connection while the switching component with operating head easily assembles to the base and is attached with two screws. They are ideal for many applications with demanding indoor and/or outdoor environments, where they may be subjected to shock or vibration from equipment, temperature extremes, dust, splashing water, coolant, and/or hose-directed water.

![]()

![]()

Application areas: