-

Differential Pressure Gauge

-

Digital Pressure Gauge

-

Stainless Steel Pressure Gauge

-

Precision Pressure Transmitter

-

Programmable Logic Controller

-

Float Level Switch

-

Pneumatic Valve Positioner

-

Temperature Transmitter Sensor

-

Hart Field Communicator

-

Solenoid Valve

-

Control Valves

-

High Accuracy Flow Meter

-

Submersible Water Pump

-

Pressure Transmitter Manifold

-

Ultrasonic Level Meter

-

Voltage Current Power Meter

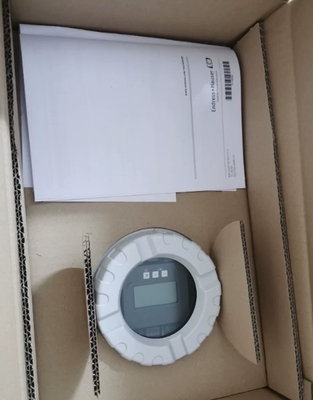

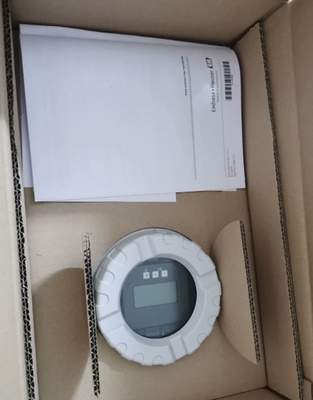

E+H Prosonic FMU41 Ultrasonic Level Sensor for Liquids and Solids

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Accuracy | +/- 2 Mm Or +/- 0,2 % Of Set Measuring Range | Process Temperature | -40 °C ... 80 °C (-40 °F ... 176 °F) |

|---|---|---|---|

| Process Pressure / Max. Overpressure Limit | 0.7 Bar ... 3 Bar Abs (10 Psi ... 44 Psi) | Max. Measurement Distance | Liquids: 8 M (26 Ft), Solids: 3.5 M (11 Ft) |

| Highlight | E+H Prosonic FMU41 ultrasonic sensor,ultrasonic level sensor for liquids,level sensor for solids with warranty |

||

Field of application

The Prosonic FMU41 sensor is suited for non-contact level measurement in fluids, pastes, coarse bulk material and flow measurement in open channels or at weirs. The two-wire or four-wire compact transmitter can be used in applications with storage tanks, agitators, on stockpiles and conveyor belts. The envelope curve can be shown on the on-site display for simple diagnosis. Linearization function (up to 32 points) for conversion of the measured value into any unit of length, volume or flow rate.

Two-wire or four wire instrument for continuous non-contact level and flow measurement.

-

Process connection: Thread

-

Temperature: -40 to +80°C (-40 to +176°F)

-

Pressure: +0.7 to +3bar (+10 to +44psi)

-

Maximum measuring distance: Liquids 8m (26ft), Solids 3.5m (11ft)

-

Blocking distance: Liquids and Solids 0.35m (1.15ft)

-

International explosion protection certificates

Benefits

-

Reliable non-contact measurement

-

Quick and simple commissioning via menu-guided on-site operation with four-line plain text display, 7 languages selectable

-

Envelope curves on the on-site display for simple diagnosis

-

Hermetically sealed and potted sensor

-

Chemically resistant sensor out of PVDF

-

Calibration without filling or discharging

-

Integrated temperature sensor for automatic correction of the temperature dependent sound velocity