-

Differential Pressure Gauge

-

Digital Pressure Gauge

-

Stainless Steel Pressure Gauge

-

Precision Pressure Transmitter

-

Programmable Logic Controller

-

Float Level Switch

-

Pneumatic Valve Positioner

-

Temperature Transmitter Sensor

-

Hart Field Communicator

-

Solenoid Valve

-

Control Valves

-

High Accuracy Flow Meter

-

Submersible Water Pump

-

Pressure Transmitter Manifold

-

Ultrasonic Level Meter

-

Voltage Current Power Meter

Original Dwyer Series 2000 Differential Pressure Gauge Magnehelic 0-60 Inch

| Connection | 1/8 NPT | Weight | 0.55kg |

|---|---|---|---|

| Temperature Limits | 20 To 140°F | Accuracy | ±2% Of FS |

| Size | 114.3*139.7mm | ||

| Highlight | 2000 Differential Pressure Gauge Magnehelic,60 Inch Differential Pressure Gauge Magnehelic,2000 dwyer magnehelic pressure gauge |

||

Original Dwyer series 2000 Differential Pressure Gauge Dwyer Magnehelic 0-60Inch

Introduction

Dial differential pressure gauges measure the difference in pressure between two points in a system and display the measurement on an analog dial display. Users can connect gauges with integral switches to a control system to respond when the measured pressure rises or falls below a set point. Gauges are available for use in low-, medium-, and high-pressure systems.

Specification

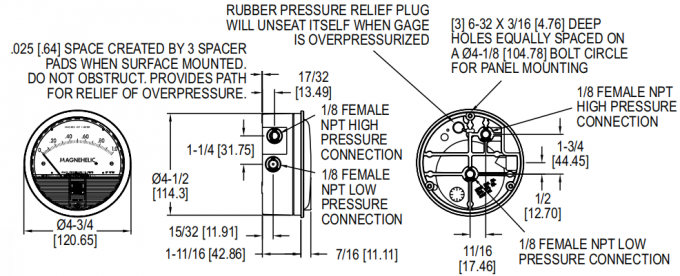

| Connection | 1/8 NPT |

| Weight | 0.55kg |

| Temperature Limits | 20 to 140°F |

| Accuracy | ±2% of FS |

| Size | 114.3*139.7mm |

Working principle

Based on the sensing element using two identical stiffness of the bellows, therefore under the same measured medium forced it to produce the same focus respectively on the legs, because of the spring leaf waiting for a moment on both sides do not produce the deflection, stent is still in the original position, the gear transmission mechanism is not action,

![]()

make the pointer still refers to the zero When applying different pressure (general high pressure end is higher than low pressure end), the force of two bellows acting on the movable bracket is not equal, so that the corresponding displacement is produced respectively, and drive the gear transmission mechanism to drive and to enlarge, indicating the differential pressure between the two after the pointer is deflect.

![]()

Performance characteristic

• Easy to read gage through undistorted plastic face permits viewing from far away

• Patented design provides quick response to pressure changes means no delay in assessing critical situations

• Durable and rugged housing and high-quality components combine to provide long service life and minimized down-time

• High accuracy option is twice as accurate as the standard Magnehelic® gage

![]()

Application areas: