-

Differential Pressure Gauge

-

Digital Pressure Gauge

-

Stainless Steel Pressure Gauge

-

Precision Pressure Transmitter

-

Programmable Logic Controller

-

Float Level Switch

-

Pneumatic Valve Positioner

-

Temperature Transmitter Sensor

-

Hart Field Communicator

-

Solenoid Valve

-

Control Valves

-

High Accuracy Flow Meter

-

Submersible Water Pump

-

Pressure Transmitter Manifold

-

Ultrasonic Level Meter

-

Voltage Current Power Meter

M-700PA Inclined Vertical Manometer High Accuracy Oil Gauge

| Temperature Limits | 140°F (60°C) | Fluid Used | Red Fluid, .826 S.g. |

|---|---|---|---|

| Material | Molded Plastic | Product Name | Red Oil Manometer |

| Highlight | Inclined Vertical Manometer,Oil Vertical Manometer,M-700PA Vertical Inclined Manometer |

||

| Accuracy | +/-3% | |

|---|---|---|

| Weight | 1.04 lb (472 g) | |

| Package Dimensions | 7.9 x 7.1 x 2.1 inches; 15.2 Ounces | |

| Range | 10-0-700 Pa |

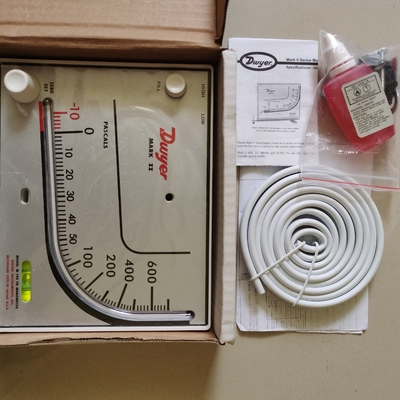

Dwyer Series MARK II M-700PA Manometer Inclined/Vertical Manometer Dwyer (10-0-700Pa) Mark II 40-25MM Red Oil Gauge

The Dwyer Mark II M-700Pa inclined differential manometer with red gauge fluid has a 10-0-700 Pa measuring range, built in zero level and molded plastic case for monitoring air velocity and air filter performance, and taking pressure measurements above and below atmospheric pressure. Red gage fluid is freeze-proof and has lower evaporation rate for use in cold environments, and produces expanded scale viewing for improved reading resolution. The built-in zero level provides linear calibration. The manometer has a styrene-acrylonitrile housing, indicating tube, and fluid wells for strength and durability. The molded ABS knobs and zero adjust plunger and shock-mounted glass level vial are wear-resistant. Leakproof O-ring seals and overflow tank reduce the risk of fluid loss. Scales are lithograph printed on aluminum to ease reading, and are epoxy coated to protect against wear. The manometer can be mounted on any vertical surface.

Dwyer Mark II Manometers come in a variety of ranges. Make sure the fluid being used is for the correct manometer.

Mark II #25, 27, MM-80 and M-700 Pa use red gage fluid (specific gravity 0.826).

Mark II #26, 28 and MM180 use blue gage fluid (specific gravity 1.9).

INSTALLATION

Position manometer on a vertical surface. Drill two 1/8˝ or 9/64˝ holes on a vertical line 3-15/16˝ apart. Loosely mount manometer with self-tapping screws provided. Adjust gage until level bubble is centered in level vial, then secure the manometer tightly.

For portable use, order optional A-612 Portable Stand.

FILLING

Turn the zero set knob counterclockwise until it stops, then turn clockwise 3 full turns. This puts zero in approximately the middle of the travel adjustment in either direction. Remove the fill plug and fill with gage fluid until fluid reaches zero on scale. Minor adjustments can be made to adjust zero by adjusting zero knob. Replace fill plug. If gage is overfilled, remove excess by inserting pipe cleaner through the fill port to blot up excess fluid.

Specifications

Pressure typesSingle and differentialMedia typeAirCase materialStyrene-acrylonitrileMeasuring range10-0-700 PaFluid typeRed gauge fluid, 0.826 sp. gr.MountStand and vertical mountAccuracy+ or - 3% full scaleMaximum pressure10psi/70kPaMaximum temperature140 degrees F/60 degrees CWeight1.04 lbs./472gDimensions5-29/32 x 7-13/32 x 2-1/4inches (H x W x D)

Manometers measure the pressure of a liquid or gas. They are used in laboratory, medical equipment, engineering, automotive, and heating, ventilation, and air-conditioning applications. Manometers measure any combination of gauge, absolute, or differential pressures. Gauge pressure is the amount of pressure in a system relative to the ambient pressure, absolute pressure is the amount of pressure in a system relative to an absolute vacuum, and differential pressure is the difference between two pressures. Analog manometers are composed of columns of liquid, and they use gravity and the liquid's density to calculate pressure. Because they have no moving parts, analog manometers do not require re-calibration. Digital manometers have pressure sensors that are connected to a system with a hose to provide a digital readout of the amount of pressure present in a system. They use microprocessors to calculate pressure, and they require periodic calibration to help ensure accuracy.

Dwyer Instruments manufactures measurement and control instruments, including pressure gauges, flow meters, level instrumentation, temperature instrumentation, and air quality monitors. The company, founded in 1931, is headquartered in Michigan City, IN.

What's in the Box?

- Mark II M-700Pa manometer

- Red gauge fluid, 1oz.

- Flexible double column plastic tubing, 8 ft.

- (2) Tubing connectors, 1/8"

- (2) Mounting screws

- Red and green pointer flags

- Instructions

![]()

![]()

![]()