-

Differential Pressure Gauge

-

Digital Pressure Gauge

-

Stainless Steel Pressure Gauge

-

Precision Pressure Transmitter

-

Programmable Logic Controller

-

Float Level Switch

-

Pneumatic Valve Positioner

-

Temperature Transmitter Sensor

-

Hart Field Communicator

-

Solenoid Valve

-

Control Valves

-

High Accuracy Flow Meter

-

Submersible Water Pump

-

Pressure Transmitter Manifold

-

Ultrasonic Level Meter

-

Voltage Current Power Meter

Elastic MC2000 Differential Pressure Gauge Stainless Steel 120mm 0-60pa

| Operating Temperature | -7~60℃ | Download | ±2.5%FS |

|---|---|---|---|

| Dial Diameter | 120mm | Material | Stainless Steel |

| Connection Location | 1/8'' | Customized Support | OEM, ODM |

| Highlight | MC2000 Differential Pressure Gauge,Differential Pressure Gauge 120mm,water pressure gauge 120mm |

||

Made in China MC Stainless Steel Differential Pressure Gauge 0-60pa

Introduction

Pressure Gauge refers to the elastic component as the sensitive component, measuring and indicating higher than the environmental pressure of the instrument, it is widely used in almost all industrial processes and scientific research fields in heat pipe network, oil and gas transmission, water supply and gas supply system, vehicle maintenance factory shop and other fields can be seen everywhere Especially in the process of industrial process control and technical measurement, the mechanical pressure gauge is more and more widely used because of its elastic sensitive element with high mechanical strength and convenient production

Specification

| Accuracy: |

|

| Connection Location: |

|

| Dial Diameter: |

|

| Type: |

|

| Customized support: |

|

| operating temperature: |

|

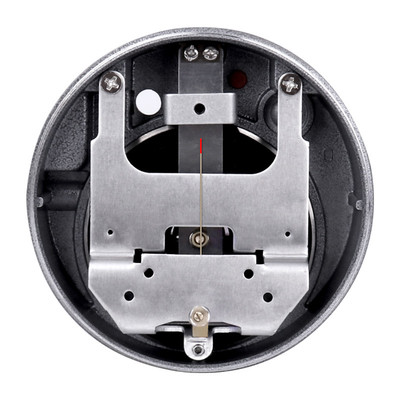

Working Principle

pressure gauge through the elastic deformation of the sensitive element (Bourdon tube bellows) in the table, and then the pressure deformation is transmitted to the pointer by the conversion mechanism of the movement in the table, causing the pointer to rotate to display the pressure

![]()

1. The upper limit of the pressure gauge is designed according to the stiffness of the external profile of the spring tube and nonlinear conditions. The upper limit of the measurement is 1 10N 1.6 10N 2.5 10N 4 10N 6 10N five series,n is a positive integer negative integer or zero .

2. Digital pressure gauge pressure range: -100kpa ~ 2kPa ~ 260MPa

3. Pressure gauge is lower than 1/3 of the measuring range part accuracy is low, not suitable for the selection of the upper measurement limit, in order to ensure the safe and reliable work of the pressure gauge, maintain its service life, generally should be greater than 1/3 of the maximum service pressure.

4. When choosing the range of use, according to the general load condition, should be used 1/3 of the full range ~ 2/3 is appropriate, because this range of use has high accuracy, and can be used under stable fluctuation of two kinds of load, the maximum range of use shall not exceed 3/4 of the full scale dial

Installing

![]()

1. The installation position of the pressure gauge should meet the requirements of the installation state. The dial should not be placed horizontally, and the height of the installation position should be convenient for staff to observe.

2. The distance between the installation place of the pressure gauge and the pressure measuring point should be as short as possible to ensure good sealing and no leakage.

3. To facilitate inspection, a cut-off valve should be installed below the instrument; When the medium is dirty or pulse pressure, filter buffer and pressure regulator can be used

![]()

High strength plastic PC cover, transparent vision, clear Angle

![]()

Product specification

![]()

![]()

![]()

![]()

Maintain:

1. After a period of use and pressure, pressure gauge movement will inevitably appear some deformation and wear, pressure gauge will produce various errors and faults in order to ensure the original accuracy and not make the value of the transfer of distortion, should be replaced in time, to ensure that the indication is correct, safe and reliable .

2. Pressure gauge should be cleaned regularly Because the internal pressure gauge is not clean, it will increase the wear and tear of various parts, thus affecting its normal work, and even make the pressure gauge fail and scrap.

3. The pressure gauge installed in the pressure measurement part, according to the provisions of JJG52-1999, its verification cycle generally does not exceed half a year For pressure gauges related to production safety and environmental monitoring, the verification period must be less than half a year according to the verification regulations. If the industrial and mining conditions are bad, the verification period must be shorter.

4. If the medium fluctuation of pressure measurement part is large, the use is frequent, the accuracy requirement is high, and the safety factor requirement is strict, the verification period can be appropriately shortened according to the specific situation.

Market application

![]()

Medical equipment livestock farms pharmaceutical plants

![]()