-

Differential Pressure Gauge

-

Digital Pressure Gauge

-

Stainless Steel Pressure Gauge

-

Precision Pressure Transmitter

-

Programmable Logic Controller

-

Float Level Switch

-

Pneumatic Valve Positioner

-

Temperature Transmitter Sensor

-

Hart Field Communicator

-

Solenoid Valve

-

Control Valves

-

High Accuracy Flow Meter

-

Submersible Water Pump

-

Pressure Transmitter Manifold

-

Ultrasonic Level Meter

-

Voltage Current Power Meter

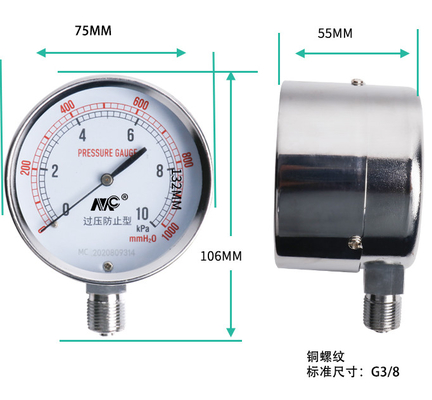

Nickel Plated Stainless Steel Pressure Gauge

| Pressure Range | 0-60kpa | Working Temperature | -25-55 |

|---|---|---|---|

| Connection | ThreadG3/8 | Size | 75mm |

| Material | Nickel Plated Brass | Display | Pointer |

| Highlight | Nickel Plated Stainless Steel Pressure Gauge,60kpa Stainless Steel Pressure Gauge,nickel plated gas pressure gauge |

||

BRAND MC Size: 75mm 0-60kpa threadG3/8 nickel plated brass YE-75 Methane gas pressure gauge Made in China

Pressure gauge

Pressure gauges are instruments designed to measure the pressure of media in a system. Measuring the pressure in your system is a critical quality step to ensure consistency of a product and safety check to be aware of leaks or building pressure in a system. Before specifying a gauge, it is important to understand the basic principles of what pressure is. Then the correct pressure gauge can be determined based on selection criteria, to accurately measure the pressure within the system. Even the best measuring equipment produces a certain deviation from the actual value. It is important to know how this measurement accuracy is defined. Digital gauges in comparison with analog ones have higher accuracy. Read our article on digital pressure gauges if you want to learn more about that type.

Specification

|

|

75mm |

|

|

0-60kpa |

|

|

2.5 |

|

|

MC |

|

|

threadG3/8 |

|

|

pointer |

|

|

nickel plated brass |

|

|

YE-75 |

![]()

![]()

![]()

![]()

![]()

![]()

Basics of Pressure & Pressure Measurement

Pressure represents the amount of force applied perpendicular to a surface per unit area. In a stagnant liquid or gas, this is the amount of force applied to the wall of the container at a given point.

Static pressure is uniform in all directions. However, a moving fluid applies additional pressure in the direction of the flow while having negligible impact on the surfaces parallel to the flow direction (Figure 1). This additional pressure is called dynamic pressure. The total pressure of a flow (also called stagnation pressure) is the sum of static and dynamic pressure in that flow.

If an instrument is facing the flow direction, it measures the total pressure of the flow. Instruments discussed here are designed to measure static pressure in a system.

Pressure is often measured in three forms:

- Absolute Pressure represents the total amount of force per unit area. A perfect vacuum has an absolute pressure of zero while earth’s atmosphere at sea level has an absolute pressure of 1 atm.

- Gauge Pressure is what most pressure gauges indicate, which is the pressure of the media relative to the atmospheric pressure. This means that gauge pressure is absolute pressure minus atmospheric pressure. If a pressure gauge is designed to measure pressures less than atmospheric pressure (known as vacuum pressure), they may be labeled as “vacuum gauge and the negative may be omitted. To signify that a pressure measurement is relative to the atmospheric pressure, the letter “g follows the unit pressure, e.g. 50 psi g.

- Differential Pressure is simply the pressure difference between two given points. Some gauges offer this measurement to provide convenience by eliminating the need to subtract two pressure readings in a system.

Types of Mounting & Connection

- Standard threaded connection: This type of gauge is simply screwed into an available thread. The threads are sealed using a compression seal for tapered threads and O-ring for parallel threads.

- Integrated pressure gauge: This pressure gauge mounting is accommodated by a female thread.

- Flange pressure gauge: This kind of mounting is offered for those who wish to install the pressure gauge onto a control cabinet.

Selection Criteria

Pressure gauges come in a wide variety of designs, each of which serve specific applications and industries. It is important to get familiarised with the factors affecting selection of the right gauge for your system. Tameson has a wide variety of articles on the various applications that pressure gauges are used for. These include swimming pool filter gauges, vacuum pressure gauges, compressor gauges, and water pressure gauges.

Read our selection tips for pressure gauges to learn more about all the factors that are needed to make a decision on a pressure gauge.

![]()

ProcessDon't need to fill liquidWith overvoltage protection function

![]()

ShellChoose iron nickel plating with corrosion resistant material, such as wear-resisting propertiesOf these, YE - 150 selects the tin phosphor bronze material

![]()

The big dial reading precisionCorrugated bellows subjected to pressure driven in a pointer

![]()

![]()